Understanding Supply Chain Circularity

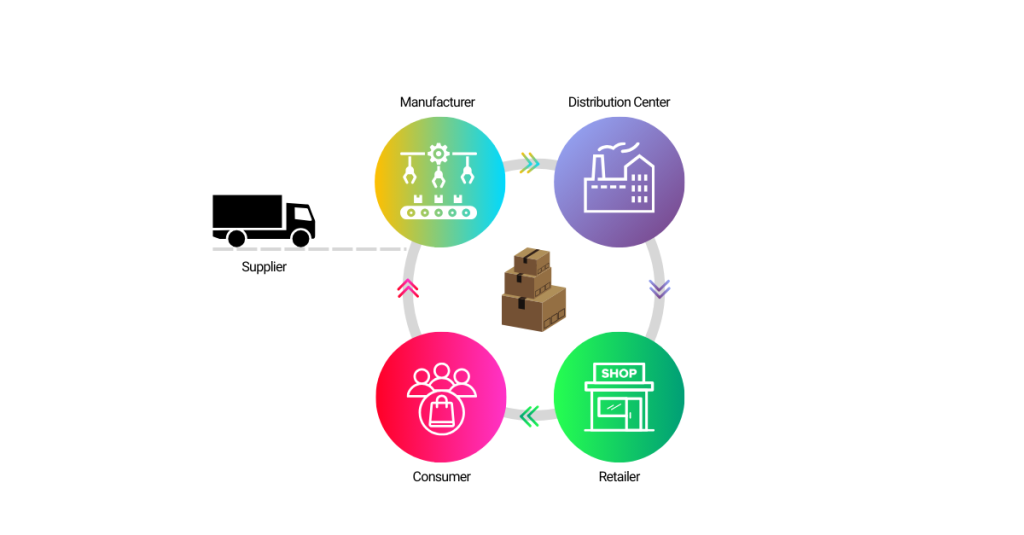

A circular supply chain is based on using materials and products for as long as possible. It functions differently than a historic supply chain, which relies on disposable products that are frequently thrown away too soon and replaced with another short-use product. In a circular setup, manufacturers reuse materials like plastic, metal, cardboard, paper, steel, and glass to prolong their useful lives. They also repair, upgrade, and sell used goods, rent products instead of selling them outright, and use eco-friendly storage and packaging such as recycled pallets. Like typical supply chains, materials and products move from suppliers to manufacturers, then retailers, and finally to consumers.

Linear vs. Circular Supply Chains

Circular supply chains operate in a closed-loop system, sending used products back to manufacturers. These supply chains prioritize the return of used products and materials back to the beginning of the chain.

On the contrary, linear supply chains contribute to the generation of significant waste as products reach the end of their life cycles. Linear supply chains move driectly from suppliers to makers, sellers, and buyers. In this setup, people normally dispose of items instead of recycling them. This waste often ends up in dumps or landfills, where it can cause significant environmental damage. It may pollute fields, rivers, or other natural environments. This disposal behavior poses environmental hazards and contributes to resource depletion and climate change exacerbation.

By transitioning from linear to circular supply chains, businesses can play a pivotal role in promoting sustainability and mitigating the adverse impacts of waste on the environment. Through the adoption of innovative practices such as product redesign, material recovery, and extended producer responsibility, companies can optimize resource use, minimize waste generation, and foster a more sustainable economy.

How Digitalization Plays a Part in This

Technology and digitalization play a crucial role in improving supply chain circularity. Rhythm Innovations has created supply chain software that can enhance circularity by providing enhanced visibility and tracking of materials and products throughout the entire supply chain. This allows companies to more effectively manage and optimize their resources, reducing waste and maximizing the reuse and recycling of materials.

Additionally, Rhythm’s supply chain software can facilitate communication and collaboration between different stakeholders in the supply chain, enabling better coordination and alignment of efforts towards circularity goals. It can also help in identifying opportunities for innovation and improvement, such as identifying waste reduction hotspots, alternative materials or redesigning products for easier disassembly and recycling.